How to Choose a Kiln | Selecting the Right Kiln

Choose the right size kiln

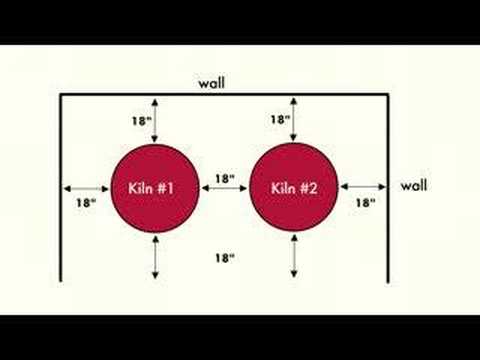

Choosing a kiln that is going to be able to fire your artwork is the single, most important thing to consider. It is the most important consideration because if your artwork does not fit, there is no way to fire it. A smaller kiln is going to be great for small artwork projects. A small kiln is ideal for testing small pieces and for beginners. But the downside is after you gain experience, your artwork size could increase, and so will your kiln size. Eventually, you will need a larger kiln. Advance potters are designing larger, more complicated artwork and need a larger kiln. You will have to decide on how long a smaller kiln will suffice. If this is a hobby, it may take several years before you need a larger kiln hence it makes sense to purchase a smaller kiln. When choosing a kiln, the space you have to work in is also a factor. If you are working in a small garage or basement then you are most likely going to be much better off with a smaller kiln. The most popular kiln size is 23 inches by 27 inches. This size is perfect for the average potter. A 29 inch by 27 inches is a little larger and is great for larger artwork. Or another way to look at it is to purchase the largest kiln you can afford. Size does not matter because you will eventually grow into it as time goes by, and you create larger and larger clay pieces.

One of my major considerations on kiln size is how much you are going to fire at once. I guess some folks will fire one piece in the kiln, but that is not the way I do it. I always fill my kiln to the maximum before firing. So obviously, if you have a large kiln, then it may take some time before you can fire the kiln because you have to fill it. It could take weeks between firings if you plan to fill your kiln. Also, a larger kiln is deeper. Therefore it requires you to bend over considerably to load and unload the kiln. If you have back problems or a weak back, this may not be a good option for you. You may want to opt-in for a smaller and shallow kiln. It will make loading and unloading much easier. Also, if you plan to create vessel sinks, using drop rings and pendant draping over tall molds, then you will need a deeper kiln. Most of my artwork is shallow therefore, I can stack them on top of one another. Just be aware that the kiln ranges in depth from a few inches to 2 feet or more. The operating cost is not going to be that much different between a kiln with a ten-inch depth as compared to a kiln with a fifteen-inch depth.

Kiln shape matters too. The kiln I am using is an octagon shape. In which I found out later after my purchase, it’s not the optimal shape. The best shape that offers the most flexibility is a rectangle or square. It is the best shape because you can always fit the largest square or rectangle in it. For example, if you have a round kiln, the largest square shape you could fire would have to fit inside the circle. A round shelve can only produce a square large enough to contain the corners. The last thing to consider when choosing a size is how much power is needed. And the general rule of thumb is of electric kilns anything over eighteen inches in size requires a 240v power source. A kiln of fewer than eighteen inches can be powered by 120v.

Choosing a gas or electric kiln

Your power source is important. As I just mentioned, if you only have a 120v power source, then you are going to be limited to a kiln under 18 inches. However, you can do as I did and call out an electrician to install a 240v power source and run a larger electric kiln. It is a very doable option. If you are interested in a gas kiln, you should look into your city or county codes and get the necessary permits. Also, you should check with your insurance and see what they will cover. Most insurance companies are fine with an electric kiln however gas kilns are a different beast. In my opinion, unless you are a commercial shop producing thousands of pieces electric is the way to go. Running gas lines, venting and hoods can cost as much as the entire gas kiln itself.

However, colors of different glazes are going to come out different in gas kilns versus electric kilns. I am not sure that matters that much for a beginner but for an advanced artist it could. In a gas kiln, the fuel uses up all the available oxygen in the chamber thus causing color changes in the glaze. Oxidation does occur in electric kilns but can produce different colors. For example, some colors like red may come out much cleaner in a gas kiln as opposed to an electric kiln. As far as my experience goes, I found that not to be a problem. What I have to do, is to fire sample clay pieces with mu colors in advance to see the actual color. This way I know for a fact what the color will look like. The bottom line is you can start with an electric kiln and, then later, several years down the road, you can always purchase a gas kiln. This way you will know exactly what you are getting into. For my purposes and artwork, I do not need a gas kiln. I will say this, in the long run, gas is cheaper to fire than an electric kiln but electric is easier to use and cheaper to install.

Choose a kiln that is simple to operate

The hardest kilns to operate are the ones that use wood as a fuel source. Witha wood kiln you have to watch the kiln the entire time monitoring the temperature and take action when it’s time to shut it down. You can spend hours upon hours checking kiln temperatures. Here is where an electric kiln comes in. An electric kiln is much easier as the temperature is controlled automatically. An electric kiln can shut itself down upon attaining a specified temperature. Another very important feature on an electric kiln is the ramp controller. Most new electric kilns come with ramp controllers. A ramp controller allows you to control the temperature by how fast you want the temperature to climb. In most cases, the kiln will hold the temperature for some time before climbing to a higher temperature. As temperatures fall, the temperature can be held for a specific time before going to a lower temperature. It depends on if you want to monitor your kiln or put a controller in charge. Some artists grow tired of the monitoring process and let the control do all the work. Some say you need to know what is going on and be in control. If you understand how to program the controller then you are in control and understand how the controller will manage temperatures and the entire firing process. It’s a matter of choice. Do you let the controller do all the work or are you willing to do it all yourself? My preference is to let the controller do all the work. I program the control so I know how the controller is going to manage the firing process. I check in every hour to visually inspect the process and see how things are going. In my opinion, letting the controller do the work is the way to go. It eliminates all the stress of remembering to take action ensuring temperatures are exactly as intended. An automatic controller does all this and assures temperatures as exactly as intended. The hardest part is setting up the automatic controller. How easy or hard depends on the brand you choose. So controls are so sophisticated it allows monitoring via your computer, tablet, or smartphone. With the touch of a button, you can check in to monitor the process without having to be there in person. But as you know all these features come at a price. Besides, some advanced features may not be available on smaller kilns.

Choosing a kiln conclusion

One last word of advice I use is to monitor the kiln firing process when the kiln has reached the highest temperature. I like to visually inspect the kiln during and near the expected shut-off. In my opinion, I wish to safeguard as much as possible to prevent an over-fire situation. The digital assistants are good but I feel more comfortable being there in person during this critical process. Digital controllers are very good and are much more accurate than the older mechanical controllers. Mechanical control is accurate to within 1 to 2 cones which translates into 40 to 80 degrees. Digital controls are accurate to within a few degrees. In my opinion you should choose a digital controller. Digital controllers are very durable however like any electronic product they can fail. The bottom line is choosing an electric kiln with a digital controller is the best way to go for beginners up to intermediate potters. Combined with its easy setup and low cost it represents the best value for kilns.

I hope this article was of use to you and you gained knowledge about how to choose a kiln. As a beginner, I mentioned basic but yet very important features to consider. I hope this gets you thinking and asking other questions that will eventually help you make an informed decision on which kiln to choose.

Additional information on klins that might help you choose

A kiln is a thermally insulated chamber, a type of oven that produces sufficient temperatures to complete processes, such as hardening, drying, or chemical changes. Kilns turn artifacts made of clay into pottery, tiles, and bricks. Different industries use rotary kilns for pyro-processing to calcinate ores, limestone to cement lime and transform many other materials.

Kilns are an essential part of all ceramics making. Ceramics require high temperatures so that there will be chemical and physical reactions to permanently alter an unfired body. In the case of pottery, clay materials are formed, dried, and fired in a kiln afterward. The final characteristics are determined by the clay body's composition and preparation, and by the firing temperature. Glazes are used after the first firing. And a second time the ware is fired to fuse the glaze into the body. To fix overglaze decoration a third firing at a lower temperature may be required. Modern kilns often have sophisticated electronic control systems, though often also use pyrometric devices.

Clay is composed of weak and porous fine-grained particles. Clay is combined with other minerals creating a workable body. Sintering is a part of the firing process. This heats the clay until the particles partially melt and flow together, creating a strong single mass composed of a glassy phase with pores and crystalline material interspersed with it. The pores are reduced in size through firing which causes the material to shrink slightly. This crystalline material consists predominantly of silicone and oxides of aluminum.

The technology in kilns is ancient. Kilns evolved from a simple earthen trench filled with pots and firing fuel pits to modern methods. Construction of a firing chamber around pots with baffles and a stoking hole was one improvement. It retained heat. A chimney stack improved the kiln's airflow or draw and thus burned the fuel more fully.

Kilns use electricity and more refined fuels, including natural gas and propane. Many large industrial pottery kilns use natural gas as it is clean, efficient, and simple to control in general. Modern kilns can be fitted with computerized controls that allow adjustments during the firing process. A user may choose to regulate the climb or ramp rate, hold or soak the temperature at any given point or control the cooling rate. Both electric and gas kilns are commonplace in industry and craft, handmade, and sculptural work for smaller-scale production.